tearing strength tester textile learner|textile tearing strength test : agent The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in .

Epic Seven Accounts for Sale. Epic Seven is a mobile RPG for iOS and Android that features high-quality, anime-styled 2D graphics. Gameplay includes a gacha summoning system and turn-based combat with a wide array of collectible characters. Control a variety of characters as you explore the game's world through its adventure mode, which is .

{plog:ftitle_list}

NSFW. ONLYFANS CATARINA PAOLINO GRATIS NO GRUPO ABAIXO. Link: https://t.me/+R1U5_zpWH-hkNDJh. 5 0. Share. u/Chemical-Carpet1846. • 1 mo. ago. .

Tearing strength is the resistance of the fabric against tearing or force required to propagate the tear once it is initiated. Generally, the resistance offered by a textile material .Textile Learner is a reference guide for textile engineering. It helps to update .

The experiment of fabric strength testing has below objects: To find out the .

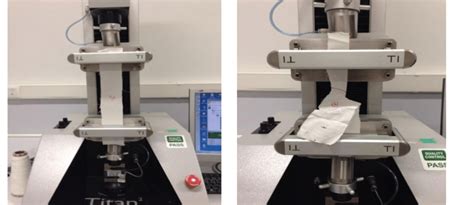

Fabric tensile strength can be tested using universal tensile strength testing . The experiment of fabric strength testing has below objects: To find out the strength of the fabric. To be precise in testing. To compare among the different fabric with standard value. To measure the deviation of the result with . The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in .

Fabric tensile strength can be tested using universal tensile strength testing equipment with suitable sample mounting jaws. There are different methods of tensile testing of fabric, which are as follows: Strip Test .

The Elmendorf tear tester is a reliable and widely used instrument for measuring tear strength in textiles. It utilizes a pendulum-based testing method to determine the force required to tear a fabric specimen.

The Elmendorf tear test is one of the frequently used methods for assessing the tearing strength of textiles. Titled after its inventor, Samuel R. Elmendorf, this test involves .The versatile PowerTear™ High Energy Elmendorf Tear Tester determines falling pendulum tearing strength by propagating a single-rip tear starting from a cut in a sample of paper, cardboard, plastic, or fabric, woven or nonwoven.

IFAI Expo 2017 New Orleans, LA. Jan P. Ballard Zeis Textiles Extension College of Textiles North Carolina State University. General Testing Information. Find 4 differences in the . The fabric’s tear strength is essential when testing fabrics’ durability and mechanical qualities. In this article, you will learn about tear strength, its importance, and how to test a fabric using ASTM D2261. Tear strength is often used to measure the performance of tent and umbrella, but knitting fabric and elastic woven fabric will not test this indicator. There are many methods to measure fabric tearing strength, such as . Vertical strength tester; Scissors; Fig: Vertical strength tester. Machine specification: Name: The Fabric Strength Tester; Brand: Goodbrand & Co. Ltd. Capacity: 250lb; Testing atmosphere: Temperature – 29 o C and .

textile tearing strength test

An introduction to tearing strength test standards. Tearing strength testing is an essential element of comparing the exceptional durability of textiles, making sure that substances meet the vital standards for numerous applications. To maintain consistency and accuracy in testing methods, standardized techniques have been established by .

textile strength testing

Apparatus used: Scissor, mm scale, Elmendorf Tearing Strength Tester; Procedure: The apparatus consist of moving clamp and fixed clamp. Prepare the sample with the help of template warp and weft. . Principles of Textile . Test Specimens: Cut ten test specimens from each swatch in the laboratory sample with each specimen being. 30mm Dia; 113mm Dia; Conditioning: Bring the specimens from the prevailing atmosphere to moisture equilibrium for testing in the standard atmosphere for textile testing Measurement. Carton strength test has been determined by this project so that it is possible to get relief from the complexity of delivering the product. . It is a single ply product made from virgin wood fibers. Known for its greater strength, high resistance to tearing, stress, punching and moisture. . Founder & Editor of Textile Learner. He is a . Lea strength tester; Electrical balance; Fig: Lea strength tester. Machine specification: The Lea Strength Tester; Goodbrand & Co. Ltd. Capacity: 100lb; Testing atmosphere: Temperature – 29 o C and relative humidity – 76%; Standard atmosphere: temperature – 20 o C and relative humidity – 65%. Sample: Size – One lea cotton yarn (1 lea .

The ASTM D5034 test method specifies a procedure to determine the maximum force and the elongation at maximum force of textile fabrics using a grab method. A grab test is a tensile test in which only the center part of the specimen (not the full width) is gripped in the jaw faces.

Tearing Strength Test of Fabric by Elmendorf Tear Strength Tester Md. Rubel Miah Department of Textile engineering World University of . Read more Perspirometer Perspiration Tester: Features, Specifications and Working PrincipleTearing Strength Test of Fabric by Elmendorf Tear Strength Tester Md. Rubel Miah Department of Textile engineering World University of . Read more Purposes, Systems and Reasons for Blending Fibres

The versatile PowerTear™ High Energy Elmendorf Tear Tester determines falling pendulum tearing strength by propagating a single-rip tear starting from a cut in a sample of paper, cardboard, plastic, or fabric, woven or nonwoven.. The versatility of the instrument allows the testing of both light and heavy weight samples while the sleek new design will enhance the .

In fact, each step of the production process has something to add to the fabric. For instance, a twill weave is far more durable compared to a plain weave. Similarly, a fabric with a higher number of yarn counts would have higher tensile strength compared to the higher tear strength of less number of threads used, and so on and so forth. 3. Count strength product or CLSP: The check quality item (CLSP) is a term utilized for staple spun yarns of cotton and the lea (hank) quality. It depends on determining the quality of the lea made on a wrapping reel having a circumference of 1.5 yards; a 80 turns lea has a total length of 120 yards. List of MCQ on Principles of Textile Testing: 1. The testing is done primarily to test the _____. a. Quality b. Quantity c. Product d. Manufacturing process. Answer: a. Quality. 2. The ability of a fabric or material to withstand wear and tear caused by friction or rubbing is _____. a. Colorfastness b. Pilling c. Strength d.

Principles of Tensile Testing; Introduction of tearing strength; Factors affecting tear strength; Measurement of fabric tearing strength; Bursting Strength. . Textile Testing Quiz-4: 34: Advanced Fibre Information System (AFIS) Textile Testing Quiz-5: Textile Testing Quiz-5: 13: Module Name Download Description 4. Rotawash Colour Fastness Tester: The rotawash is a laboratory instrument used for conducting accelerated laundering or dyeing tests. It is applicable for performing washing, dry cleaning, dyeing, colorfastness to .

wolpert wilson portable hardness tester

Figure 2.2: Button direct pull strength tester. 2.2.4.3 Button pull strength test machine calibration A specific template uses to calibrate the machine to find out the accuracy of a machine of known weight. [15] 2.2.4.4 .

wolpert wilson rockwell hardness tester

A number of tear strength test is carried out and the average is taken to determine the tear strength. Tearing strength is expressed either in pounds or grams. Purpose: To demonstrate the proper way of the . The polyorganosiloxane-based material of the second layer exhibits a tear-strength of at-least 30 KN/m. The benefit of using silicone-coated compositions over other, e.g. organic coating compositions, lies e.g. in the improved weather ability, ability to maintain flexibility and heat resistance of the silicone-based composition.

Enzyme washed denim fabric was tested for tensile strength, tearing strength, stiffness and drapeability. 2.3 Testing and Analysis: Treated fabric was conditioned at 65 % RH and at 20 o C for 24 hours before testing. Tensile strength was determined by the US Standard Grab test method according to ASTM D 5034. Seam Slippage Test: This test method is used to determine the resistance to slippage of filling yarns over warp yarns , or warp yarns over filling yarns, using a standard seam. The machine setup for the seam slippage test is similar to that for the seam strength test, except that a cross-head speed of 50 mm/min is usually used. Fig: Seam .

Biological testing Textile fabrics may be adversely affected by various microorganisms and insects. The effect of biological agents on textile fabrics is important for enhancing their end-use performance in many areas. Testing of fabrics and evolution of specific test methods for the above biological influences would help manufacturers, retailers and users .What is Elmendorf Tear Tester?. The Elmendorf Tear Tester is a widely used instrument in material testing. It is specifically designed to measure the tear resistance of various materials, including films, paper, textiles, and non-woven fabrics.This testing method helps in assessing the material’s ability to withstand tearing forces, providing valuable insights into its quality and . D 2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data. D 2906 Practice for Statements on Precision and Bias for Textiles3. . 6.1.4 The fabric tearing strength tester should be capable of providing interchangeable full-scale force ranges. Typical full-scale ranges are shown in Table A3.1. Intern at Textile Learner Email: [email protected] . It decreases the tensile strength and tear strength. It decreases the abrasion resistance. It gives unpleasant odor. . Determination of Fabric Crease Recovery by Shirley Crease Recovery Tester; Classification of Textile Testing: Fiber Testing, Yarn Testing, Fabric Testing .

The force needed to tear a fabric is known as its tear strength, an important test ASTM D2261 determines a fabric’s capacity to withstand damage with time. . GB/T3917 = The ballistic pendulum (Elmendorf) method for determining the tear force of textile textiles is described in GB/T 3917. BS 4303 = It describes a wing rip tear test method.Tearing Strength Test of Fabric by Elmendorf Tear Strength Tester Md. Rubel Miah Department of Textile engineering World University of . Read more Fabric Bursting Strength Test by Diaphragm & Ball Method

Concept of Tearing Strength Local yarns in fabrics tear in residual rent due to concentrated loads, which is called tearing phenomenon of fabrics. For example, when the fabrics are caught by objects, local yarns will be forced to tear in rent; or the parts of the fabrics are held and torn in half. In general, tearing.

tearing strength tester

WEB@The_RR34 is a Twitter user who posts rr34 animations and drawings of various characters, mostly from video games and anime. Check out his latest tweet on 2020-10 .

tearing strength tester textile learner|textile tearing strength test